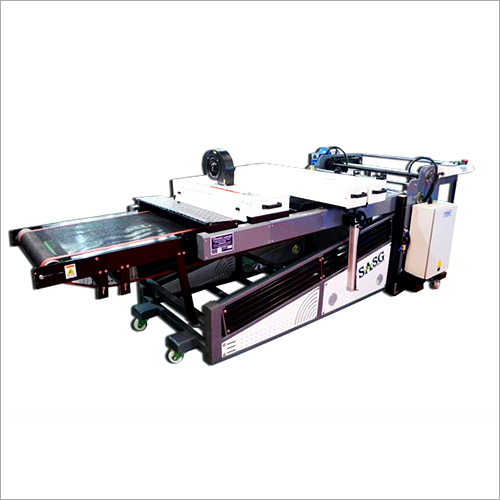

यूवी क्योरिंग सिस्टम

उत्पाद विवरण:

- बेल्ट का प्रकार Heat Resistant

- विशेषताएँ Fast curing, Uniform exposure, Energy efficient

- पावर सोर्स Electric

- सतह की फ़िनिश Powder Coated / Polished

- मोटाई 2-5 mm (belt) / Customizable body

- मटेरियल Stainless Steel / Mild Steel

- टाइप करें

- अधिक देखने के लिए क्लिक करें

यूवी क्योरिंग सिस्टम मूल्य और मात्रा

- 1

- , टुकड़ा/टुकड़े

- आईएनआर

- टुकड़ा/टुकड़े

यूवी क्योरिंग सिस्टम उत्पाद की विशेषताएं

- Customizable as per requirement

- Electric

- Fast curing, Uniform exposure, Energy efficient

- Adjustable

- 2-10 kW (depending on model)

- Heat Resistant

- 220-415 V

- Stainless Steel / Mild Steel

- Industrial, Printing, Wood, Glass, Plastic, PCB, Coating

- 2-5 mm (belt) / Customizable body

- Powder Coated / Polished

यूवी क्योरिंग सिस्टम व्यापार सूचना

- प्रति सप्ताह

- महीने

- customize packing

- ऑल इंडिया

उत्पाद वर्णन

UV curing system is employed by the manufacturers of different sectors, as it improves gloss. Also, it provides better resistance against scratches as well as abrasion. This is accessible with excellent chemical resistance, optimum hardness, greater strength, boosted elasticity and excellent adhesion. UV curing system is provided with clear optical quality as well as enhanced durability in high temperature settings. The curing of inks, glues, adhesives, and bonds takes place in an environment-friendly manner. Consistency in production process is ensured. Another benefits are immediate processing, fast curing & quality control, utilization of solvent-free coating system. With their use, there is no need of solvent recycling or after burning.

High-Intensity UV Technology for Fast, Uniform Curing

Utilizing advanced high-intensity UV lamps with selectable wavelengths (365, 385, 395 nm), this curing system delivers rapid and consistent results across various materials. The digital/PLC control system ensures precise operations, while the robust stainless or mild steel construction provides enhanced durability, making it well-suited for demanding industrial applications.

Customizable Design to Match Your Workflow

Tailor the UV Curing System to your process requirements with customizable dimensions, workpiece sizes, and load capacities. Options such as vertical or pneumatic conveyors, along with heat-resistant PU belts and roller conveyors, adapt to multiple manufacturing setups, ensuring seamless integration into your production line.

Safety, Efficiency, and Low Maintenance Assured

This system prioritizes user safety with features like emergency stop and overheat protection. Air- or water-cooled mechanisms maintain lamp performance and extend its 800010000 hour lifespan. With a powder-coated and corrosion-resistant finish, the machine is engineered for minimal maintenance and maximum energy efficiency over years of continuous operation.

FAQs of UV Curing System:

Q: How does the UV Curing System ensure uniform exposure and fast curing for different materials?

A: The system utilizes a high-intensity UV lamp with selectable wavelengths (365 nm, 385 nm, or 395 nm), ensuring optimal light absorption for various substrates such as wood, glass, plastic, and PCBs. Digital/PLC control enables precise adjustment of curing speed and intensity, delivering consistent, fast, and uniform curing results.Q: What are the customization options available for workpiece size, load capacity, and system dimensions?

A: The UV Curing System is designed to accommodate specific production needs. Workpiece size, system dimensions (L*W*H), and load capacity can all be customized. Conveyor choicesincluding belt, roller, vertical, or pneumatic systemsallow further adaptation to your manufacturing workflow.Q: When should maintenance be performed, and how easy is it to maintain the system?

A: Routine maintenance is minimal thanks to its low-maintenance design, corrosion-resistant materials, and robust construction. Lamp replacement is typically required after 800010000 hours of use. Regular inspection of cooling systems and conveyor belts is recommended to maintain peak performance.Q: Where can the UV Curing System be installed, and what are its installation requirements?

A: This floor-mounted system can be installed in diverse industrial environments, such as printing plants, wood workshops, plastic fabrication units, and PCB manufacturing facilities. It requires a suitable electric supply (220415 V), space for customizable dimensions, and may need ventilation for air or water cooling depending on the selected model.Q: What safety features are incorporated in the UV Curing System?

A: Safety is ensured through built-in emergency stop buttons, overheat protection for the lamp and electronics, and a robust, fully-enclosed structure. These features help prevent operator injury and protect the machine, even during prolonged or high-intensity operation.Q: How does the cooling system operate, and can it be adapted for different environments?

A: Depending on your requirements, the UV Curing System can be equipped with either an air-cooled or water-cooled mechanism. The choice can be tailored to the ambient temperature of your facility, the intensity of curing, or energy efficiency preferences.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+