SASG Offset Fountain Chilling And Circulating Unit

200000 INR/Unit

Product Details:

- Type Offset Fountain Chilling And Circulating Unit

- Material Mild Steel (Powder Coated Body)

- Power 1.0 KW

- Power Source Electric

- Voltage 220-240 V AC, 50 Hz

- Capacity Standard (customizable as per requirement)

- Loading Capacity 120-250 Litres Per Hour (L/hr)

- Click to View more

X

SASG Offset Fountain Chilling And Circulating Unit Price And Quantity

- 1 Unit

- 200000 INR/Unit

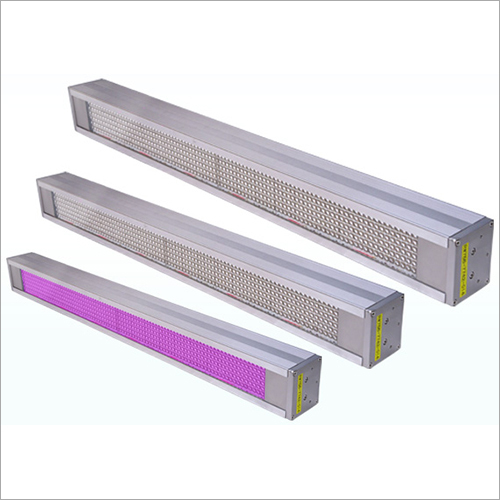

SASG Offset Fountain Chilling And Circulating Unit Product Specifications

- Approx. 1200 x 660 x 1060 mm

- Yes

- Offset Fountain Chilling And Circulating Unit

- Standard (customizable as per requirement)

- Electric

- 5C to 25C

- Mild Steel (Powder Coated Body)

- Grey/Blue

- 1.0 KW

- 220-240 V AC, 50 Hz

- 120-250 Litres Per Hour (L/hr)

- 95 kg (Approx.)

- 5C to 25C

SASG Offset Fountain Chilling And Circulating Unit Trade Information

- 1 Unit Per Month

- 1 Months

Product Description

SAGS Offset Fountain Chilling and Circulating Unit removes heat based on the principle that heat will move from a hotter source to a colder source, from the process to a conditioned fluid. This comprise two main parts called circuits, a refrigeration and a fluid circuit. The two circuits work in concert to transfer heat away from the process and maintain a reasonably constant process temperature. SAGS Offset Fountain Chilling and Circulating Unit is considered plumbing fixtures and are directly connected to plumbing potable water and drainage systems. Water to the unit is supplied either from a remote, central chilled water unit or ambient temperature water from the potable cold-water system. This plant is very effective and economical both.

Advanced Cooling Performance

The SASG Offset Fountain Chilling and Circulating Unit leverages a high-efficiency hermetically sealed compressor and a water/glycol mixture as its cooling medium, ensuring effective heat dispersal in demanding environments. The automatic defrost operation and precise digital temperature control guarantee reliable and consistent cooling suited to a wide range of industrial needs.

User-Friendly Design and Operation

Operating this unit is straightforward, thanks to its LED operational display and digital temperature controller. Its heavy-duty circulation pump and standard hose fittings make installation and connection effortless. Mounted on robust casters, the unit offers exceptional portability for adaptable site use.

Safety and Durability Assured

Constructed from powder-coated mild steel, the chiller is built for longevity. Integral safety featuressuch as overload protection and high/low pressure cut-offsafeguard both the operator and equipment, reducing downtime. Its low-noise operation and sturdy build make it ideal for continuous performance in busy operational environments.

FAQs of SASG Offset Fountain Chilling And Circulating Unit:

Q: How does the SASG Offset Fountain Chilling and Circulating Unit maintain precise temperature control?

A: The unit is equipped with a digital temperature controller that allows users to set and maintain temperatures between 5C and 25C. The hermetically sealed compressor and efficient circulation pump work in tandem to ensure stable and accurate cooling throughout operation.Q: What are the typical use cases for this circulating unit?

A: This unit is commonly used in industrial processes where consistent cooling is essential, such as in printing, plastics, food processing, or laboratory equipment. Its reliable temperature control ensures optimal equipment performance and product quality.Q: When should the units water/glycol mixture be checked or replaced?

A: It is recommended to check the water/glycol mixture regularly, especially before extended use. Replacement schedules depend on usage intensity, but periodic inspection helps maintain efficient heat transfer and prevents system fouling.Q: Where can the chilling and circulating unit be installed?

A: Thanks to its heavy-duty casters, the unit can be positioned easily in factories, workshops, or any setting requiring localized cooling. It operates effectively on standard 220240 V AC power, making it suitable for most industrial environments.Q: What safety features are integrated into the unit?

A: The system includes overload protection as well as high and low pressure cut-off mechanisms. These safeguards automatically protect the compressor and components from electrical surges or operational irregularities, ensuring long-term equipment durability.Q: How can I connect the chiller to my existing setup?

A: The unit features standard hose fittings for both inlet and outlet, enabling quick and secure integration with a wide variety of process equipment. The heavy-duty circulation pump ensures consistent flow to and from your devices.Q: What are the main benefits of using the SASG Offset Fountain Chilling and Circulating Unit?

A: Key benefits include precise temperature management, low-noise operation, easy mobility, robust safety features, and customizable capacity. These attributes ensure your processes run efficiently, safely, and with minimal interruption.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free