SASG Water Air Chilling Plants

100000 INR/Unit

Product Details:

- Type Water Air Chilling Plant

- Material Mild Steel

- Power Electric

- Power Source Electric

- Voltage 220V/380V

- Capacity 0.5 TR to 100 TR

- Loading Capacity Customizable as per requirement

- Click to View more

X

SASG Water Air Chilling Plants Price And Quantity

- 1 Unit

- 100000 INR/Unit

SASG Water Air Chilling Plants Product Specifications

- Electric

- Up to -20C

- Varies by model

- Yes

- -20C to +15C

- Blue & White

- Electric

- 0.5 TR to 100 TR

- As per model specification

- Customizable as per requirement

- Mild Steel

- 220V/380V

- Water Air Chilling Plant

SASG Water Air Chilling Plants Trade Information

- 1 Unit Per Month

- 1 Months

Product Description

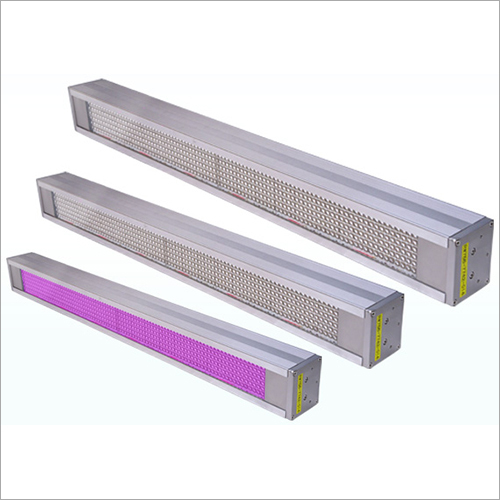

SASG Water Air Chilling Plants remove heat from a liquid via a vapor-compression, Adsorption refrigeration, or absorption refrigeration cycles. These plants act as a mechanical device used to facilitate heat exchange from water to a refrigerant in a closed loop system. The refrigerant is then pumped to a location where the waste heat is transferred to the atmosphere. SASG Water Air Chilling Plants are designed and developed by our experts. We offer our chilling plant with excellent efficiency and functions. These plants are widely used and effective as well as can be easily purchased by our valued customers at nominal pricing, as per their requirements. This plant is very easy to install and simple to operate too.

Reliable Cooling for Every Industrial and Commercial Need

SASG Water Air Chilling Plants deliver dependable temperature control with customizable capacities and advanced safety features. Available in varied models to suit specific space and performance requirements, these plants feature advanced compressor and condenser technology for optimal efficiency. With a robust mild steel build and sleek blue & white finish, they are designed for long-lasting, low-maintenance use.

Advanced Control and Flexible Installation Services

Every unit is equipped with a fully automatic microprocessor-based control panel, enabling seamless operation and effortless monitoring. SASG provides comprehensive site installation services across India, ensuring each system is expertly configured to your specifications. These plants are suitable for fluctuating industrial demands and can be tailored to precise cooling temperatures, from -20C to +15C.

FAQs of SASG Water Air Chilling Plants:

Q: How is the SASG Water Air Chilling Plant installed at my site?

A: Our expert technicians provide on-site installation services across India. Each chiller is carefully assembled and configured as per your space requirements and customized specifications, ensuring optimal performance from the outset.Q: What types of refrigerants and compressors are available for customization?

A: The plant can be customized with R22, R407C, or R134A refrigerants and is available with hermetic, scroll, or semi-hermetic compressors. This flexibility ensures compatibility with a wide range of cooling applications and operational preferences.Q: When is automatic defrost operation activated in these chilling plants?

A: Automatic defrost operation is managed by the integrated microprocessor controller, which monitors system conditions and initiates defrost cycles as needed to preserve efficiency and prevent ice build-up.Q: Where are these water air chilling plants typically used?

A: They are widely utilized in industrial and commercial settings, such as manufacturing facilities, food processing units, pharmaceutical plants, and large office buildings, where reliable, low-temperature cooling is essential.Q: What is the process for customizing loading capacity and dimensions?

A: Once your application requirements are understood, we tailor the loading capacity (from 0.5 TR to 100 TR) and physical dimensions to seamlessly fit your operational needs and space constraints.Q: How does the fully automatic control panel benefit users?

A: The microprocessor-based control panel streamlines system operations, offers precise temperature management, and enables quick troubleshooting, thereby reducing manual intervention and enhancing overall efficiency.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email